Cart

CloseNo products in the shopping cart.

No products in the shopping cart.

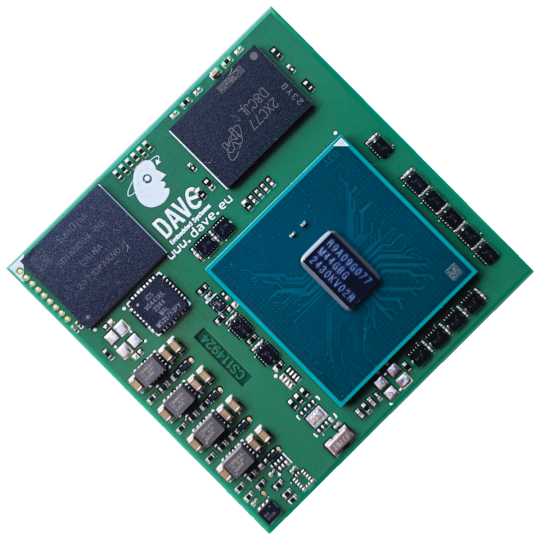

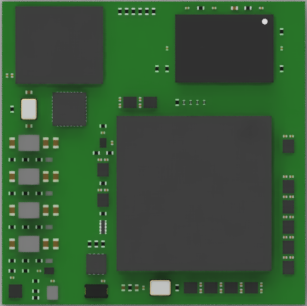

Renesas RZ/T2H - ZERO SOM

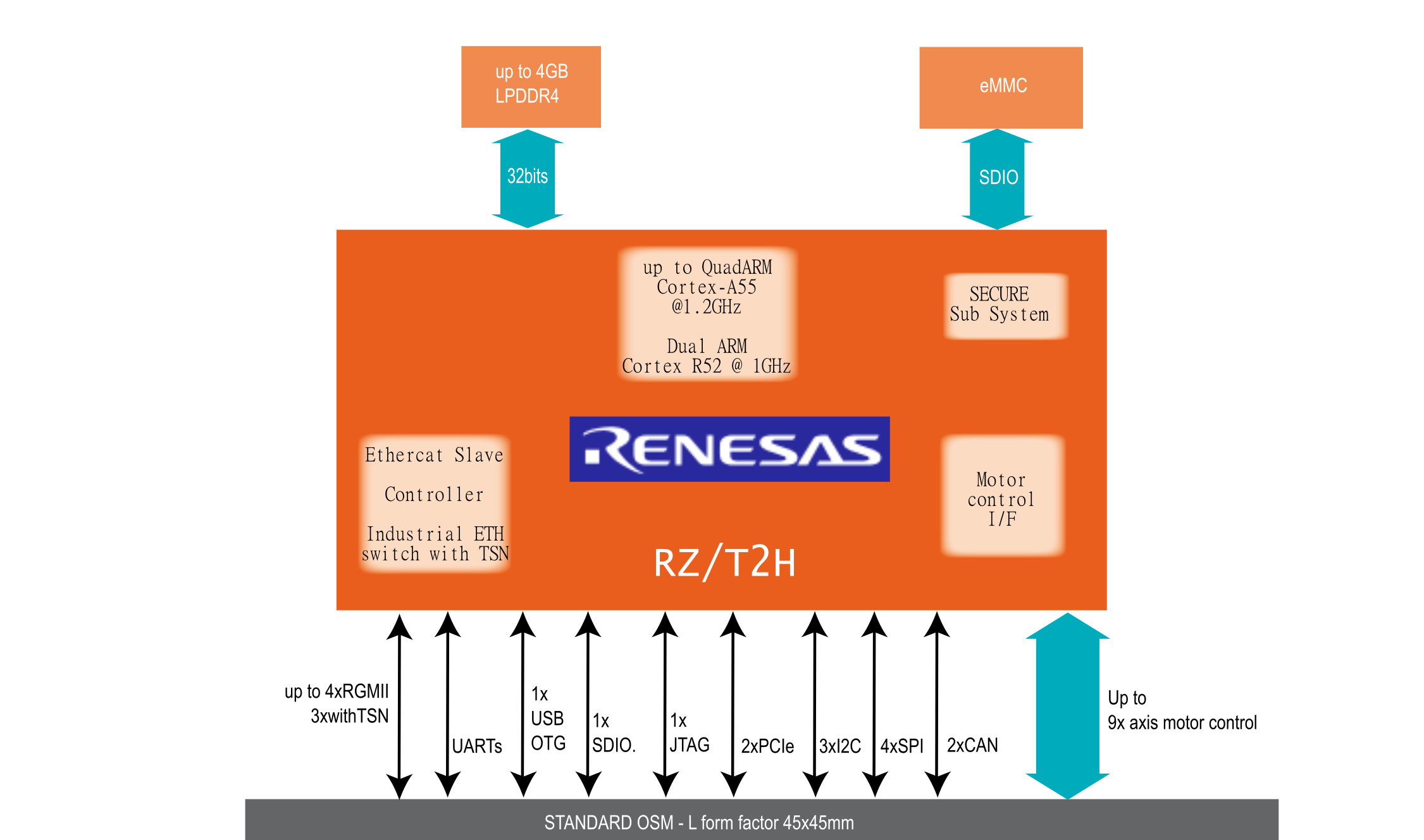

Featuring a complete suite of internal processing units and peripherals, the ZERO SOM includes up to 3 industrial MAC Ethernet ports, up to 9 motor control axes, and a safety management system, making it ideal for industrial, safe, and secure connected applications.

The ZERO SOM is integrated into ToloMEO, DAVE Embedded Systems' solution for Edge Data Orchestration and Industry 5.0. With ToloMEO, the ZERO SOM is natively connected to the cloud, enabling data collection and remote OTA updates. It also supports the integration of machine learning algorithms running on the internal ARM cores and PRU. Additionally, it manages edge activities within a Trust Zone Area for legally bound supply chain transaction management. Cybersecurity protection is ensured through VCE monitoring and security update applications. Finally, the Embedded Manager module supervises the software lifecycle and BSP design.

The ZERO SOM is specifically designed for safe and reliable industrial applications and is suitable for IEC 61508 compliance. With ToloMEO, the ZERO SOM is the ideal solution to design a fleet of edge devices compliant with standard regulations for security and data protection.

Key Features

|

|

CPU |

|

| Memory |

|

| Interfaces (full-spec models) |

|

| Mechanical |

|

Power Supply |

|

| BSP |

|

ZERO is a System on Module (SoM) based on the Renesas RZ/T2H microprocessor, specifically designed for high-performance real-time applications. Thanks to its advanced ARM Cortex-R52 cores and integrated industrial features, ZERO is ideal for motion control, robotics, factory automation, and other time-critical embedded systems.

ZERO offers a combination of high computing power, real-time determinism, and industrial connectivity. Developers benefit from reduced design complexity, optimised time-to-market, and a scalable hardware platform fully supported by DAVE Embedded Systems.

ZERO is powered by the Renesas RZ/T2H microprocessor, featuring multiple ARM Cortex-R52 cores, hardware accelerators, and advanced peripherals designed to meet the demanding needs of industrial automation and real-time processing.

By using ZERO, engineers can focus on application development rather than hardware complexity. The module integrates all key functions, provides long-term availability, and reduces both risk and cost of custom board design.

ZERO is backed by DAVE Embedded Systems’ full range of technical support services, including documentation, software development kits, and direct assistance from the engineering team. This ensures a smooth integration of ZERO into industrial projects.

Yes, ZERO integrates a wide range of industrial connectivity options, including Ethernet, fieldbus interfaces, and serial communication. This makes ZERO suitable for real-time industrial networks and interoperability with existing automation systems.

ZERO adopts a compact and robust form factor (45x45mm), optimised for industrial environments. This design ensures mechanical stability, simplified integration, and flexibility in custom carrier board development.

ZERO is designed with energy efficiency in mind. Thanks to the Renesas RZ/T2H microprocessor and advanced power management, ZERO achieves high computing performance while maintaining optimised power consumption for embedded and industrial applications.

Yes, ZERO is part of the DAVE Embedded Systems’ Longevity Program, which guarantees product availability for an extended period of time. The program ensures proactive lifecycle management, long-term supply stability, and continuous support, making ZERO a reliable choice for industrial applications with long product lifecycles.

Read more on the official Wiki: ZERO SOM Longevity Program.

ZERO is designed to be compatible with DAVE Embedded Systems’ ecosystem of System on Modules. This allows customers to benefit from design reuse, scalability across product families, and simplified migration between platforms.

ZERO comes with a full software ecosystem, including Board Support Package (BSP), development kits, and technical documentation. These resources accelerate software development and ensure optimised integration of ZERO into industrial applications.

You can download the official ZERO brochure in PDF format, which provides a complete overview of the System on Module and its key features: download the ZERO brochure

Please note: to access this document, you must be registered on the DAVE Embedded Systems website.

If you are not yet registered, follow this short video guide to create your account: How to register to the DAVE Embedded Systems website

The part number (P/N) of ZERO is a structured code that identifies the specific configuration and features of the System on Module. Each element of the Part Number corresponds to a hardware option, ensuring clear identification and traceability of the product.

You can find how the ZERO part number is composed on the official DAVE Embedded Systems Wiki: ZERO SOM P/N composition.

Projects that integrate ZERO benefit from guaranteed supply continuity, proactive lifecycle management, and direct technical support from DAVE Embedded Systems. These advantages make the Longevity Program a key factor in reducing risks and ensuring long-term reliability of industrial solutions.

All official hardware documentation for ZERO, including schematics, mechanical drawings, and design guidelines, is available on the DAVE Embedded Systems Wiki: ZERO Hardware documentation.

Yes, the ZERO Hardware Manual has been made available by DAVE Embedded Systems. This official document, prepared by our engineering team, provides detailed information to support hardware design and integration. Access the ZERO Hardware Manual (PDF).

Please note: to access this document, you must be registered on the DAVE Embedded Systems website. If you are not yet registered, follow this short video guide to create your account: How to register to the DAVE Embedded Systems website

The core of the ZERO System on Module is built around the Renesas RZ/T2H application processor, supported by a dedicated power supply unit, high-speed LPDDR4 memory, and reliable eMMC flash storage. All these elements are integrated in the compact OSM L 45x45mm form factor, making ZERO an efficient and robust solution for industrial applications.

For a detailed overview of these components, you can visit the page dedicated to the processor and memory subsystem of ZERO.

ZERO System on Module adopts well-established hardware versioning and tracking mechanisms to ensure product identification and lifecycle traceability. The PCB version is copper-printed directly on the board, while the serial number is provided on a dedicated white label. In addition, a ConfigID is used by the software running on ZERO to identify the specific product model and hardware configuration. These mechanisms simplify maintenance, support, and reliable integration of ZERO in industrial projects.

If you want to explore these aspects in more detail, you can read the dedicated section on hardware versioning and tracking of ZERO.

To request a quote for ZERO, please visit the dedicated Get a Quote page on the DAVE Embedded Systems website and fill out the form.

The ZERO System on Module provides a full set of connectors designed according to the OSM Size-L standard. The pinout table describes in detail all available signals and interfaces, allowing developers to correctly integrate ZERO into custom carrier boards and ensure reliable connectivity in industrial applications.

For the complete pinout reference, you can consult the dedicated ZERO SoM pinout table.l System on Module ZERO mette a disposizione un set completo di connettori, progettati secondo lo standard OSM Size-L. La tabella del pinout descrive in dettaglio tutti i segnali e le interfacce disponibili, consentendo agli sviluppatori di integrare correttamente ZERO in carrier board personalizzate e garantire connettività affidabile nelle applicazioni industriali.

Per consultare il riferimento completo al pinout, puoi visitare la pagina dedicata alla tabella del pinout di ZERO

ZERO System on Module integrates a dedicated Power Supply Unit (PSU) designed to provide stable and efficient power to the Renesas RZ/T2H processor and all onboard peripherals. To guarantee reliable operation, a recommended power-up sequence must be followed: this ensures that each voltage rail is applied in the proper order, avoiding malfunctions or damage. Correct PSU design and compliance with the sequence are crucial for integrating ZERO into industrial-grade systems.

For detailed guidelines and diagrams, you can refer to the section on the ZERO power supply unit and recommended power-up sequence.

ZERO System on Module implements a dedicated reset scheme that ensures the correct initialization of the Renesas RZ/T2H processor and all peripherals. The design includes specific control signals that manage reset states, guaranteeing predictable behaviour during startup and recovery phases. These mechanisms are essential to maintain system stability, simplify debugging, and support reliable integration of ZERO in industrial environments.

If you need a detailed explanation of the signals and their timing, you can consult the section on the ZERO reset scheme and control signals.

The system boot of ZERO is designed to ensure a reliable and flexible startup sequence for the Renesas RZ/T2H processor. At power-on or reset, the boot process defines how the SoM loads the initial code and activates the selected memory and peripherals. This mechanism allows developers to configure ZERO according to the requirements of their industrial application, guaranteeing both predictable behaviour and robust integration.

For a detailed description of the sequence and available options, you can refer to the section on the ZERO system boot process.

Yes, ZERO System on Module provides JTAG support, a standard interface widely used for hardware-level debugging and testing. Through JTAG, developers can access the internal states of the Renesas RZ/T2H processor, monitor signals, and control execution flow, which simplifies troubleshooting and speeds up development cycles. This feature is essential in industrial contexts where reliability and precise debugging are critical.

For complete details on the available interface and usage recommendations, you can visit the section on JTAG support in ZERO.

ZERO System on Module offers a wide range of integrated peripherals that make it suitable for complex and connected industrial applications. Available interfaces include Ethernet, USB, PCIe, SD, CAN, Serial, I2C, SPI, LCD, Timer, PWM, ADC, Industrial interfaces, Real Time Clock, Watchdog, GPIOs, Temperature Sensor and Security.

This rich set of peripherals enables flexible system design, simplifies connectivity, and supports demanding real-time requirements.

For a full technical overview of each interface, you can explore the documentation dedicated to ZERO hardware resources.

ZERO System on Module is designed with industrial-grade operational characteristics to ensure stable and reliable performance in demanding environments.

The module specifies electrical, thermal, and mechanical parameters that define safe operating ranges, such as supply voltages, power consumption, and temperature profiles. Adhering to these specifications is fundamental to guarantee long-term reliability and robust integration of ZERO in embedded applications.

If you want to explore the detailed values and conditions, you can read the section on the operational characteristics of ZERO.

ZERO System on Module is designed with careful attention to thermal management to ensure stable performance under industrial operating conditions. The module specifies how heat is generated and dissipated, helping developers evaluate the thermal profile of their design.

Proper heat dissipation is essential to maintain safe junction temperatures, protect components, and guarantee long-term reliability of ZERO in embedded applications.

For detailed recommendations and design guidelines, you can consult the section on thermal management and heat dissipation of ZERO.

ZERO System on Module follows the OSM Size-L standard, featuring a compact 45 x 45 mm form factor optimised for industrial integration. The mechanical specifications define dimensions, thickness, and connector placement, ensuring compatibility with carrier boards and robustness in demanding environments.

These characteristics simplify mechanical design, guarantee repeatability in production, and reduce integration risks when adopting ZERO in embedded projects.

For detailed drawings and dimensional constraints, you can consult the section on the mechanical specifications of ZERO.

The block diagram of ZERO is shown on the product page.

For quick reference, you can also access the image directly via this link: ZERO Block Diagram.

Customers are strongly encouraged to register their ZERO kit to gain access to reserved content such as source code and additional documentation.

To register, simply send an email to helpdesk@dave.eu including the kit Part Number (P/N) and Serial Number (S/N).

All application notes related to ZERO will be published over time in the dedicated section of the Wiki.

Stay updated here: ZERO Application Notes

All technical notes for ZERO will be made available over time in the appropriate section of the Wiki.

Follow updates here: ZERO Technical Notes

White papers related to ZERO will be gradually released in the specific section of the Wiki.

Access the section here: ZERO White Papers

Case histories featuring ZERO will be shared over time in the relevant section of the Wiki.

Browse the section here: ZERO Case Histories

To request support from the DAVE Embedded Systems technical team, please fill out the Helpdesk form available at this link: Online Technical Helpdesk.

Once submitted, a support ticket will be generated. Our technicians will review your request and typically respond via email within 24 hours.

No worries — if you need to return your ZERO module, DAVE Embedded Systems has a dedicated RMA (Return Material Authorisation) process in place.

Just head to this page and follow the instructions to submit your request: Return Material Authorisation – RMA Procedure

Once submitted, you’ll receive a ticket and further details via email.

DESK-RZ-L is the official development kit provided by DAVE Embedded Systems to accelerate software design on platforms based on the Renesas RZ family, including ZERO.

It integrates documentation, board support packages (BSPs), preconfigured development environments, and application examples. By using DESK-RZ-L, engineers can reduce setup time, simplify debugging, and focus directly on application development, ensuring a faster and more reliable integration of ZERO into industrial projects.

For more information and access to resources, you can visit the dedicated section on DESK-RZ-L.

Welcome to the DAVE Embedded Systems' technical information form submission portal!

Please fill in the fields below. The support team will take care of you in maximum 24h!

Welcome to the DAVE Embedded Systems' Documentation system. Please fill in with required information and you will get your document! Thank you!.

We use cookies to personalize content, to get traffic statistics and to improve your experience on our website.

Please read our Cookie Policy for a more detailed description and click on the "Manage preferences" button to customize how the site uses cookies for you. By clicking on "Accept all cookies" you give your consent for the use of each type of cookie.

These cookies are necessary for the website to function and cannot be switched off in our systems.

You can set your browser to block or alert you about these cookies, but some parts of the site will not then work. These cookies do not store any personally identifiable information.

These cookies allow us to count visits and traffic sources so we can measure and improve the performance of our site. They help us to know which pages are the most and least popular and see how visitors move around the site.

All information these cookies collect is aggregated and therefore anonymous. If you do not allow these cookies we will not know when you have visited our site, and will not be able to monitor its performance.

Select all Deselect all