Carrello

ChiudiNessun prodotto nel carrello.

Nessun prodotto nel carrello.

Crane machine display system for harbour goods logistics

THE SCENARIO:

In a globalized world like ours, the traffic of goods represents one of the triggers of the social revolution we are witnessing. The world became smaller: assets and labor have broken down borders, making the planet an exchange territory as never before. Therefore, the correct management of goods is of fundamental importance in maintaining the current state. In particular, one of the most frequent means used for moving products between distant countries is the transportation of containers by sea, hence harbors play a key role in today's economy.

The journey of the goods in a dock is certainly not concluded and they will have to continue a very long trail before they reach the desired destination. However, since it is not possible to enter any city by sea, goods must necessarily change the means of transport: and this is where the fundamental role of crane machines is revealed. Their incredibly important task, however, is particularly delicate and their human operator must pay close attention to the maneuvers made since lifting too quickly or too much weight can lead to enormous damage to goods, machines, and operators themselves.

THE CONTEXT:

The principles of archimedean physics involved in these movements and loads are too complex to be calculated from time to time by the driver, therefore it should be a task of the cranes themselves to verify the real parameters received as input from the surrounding environmental conditions and to warn the operator on how to execute them and on any dangerous situations that could arise.

For this significant project, therefore, it is necessary to develop automotive platforms capable of communicating with the user in a bidirectional way through an intuitive and easy-learning graphic interface, also by detecting commands and settings entered by the operator and acting accordingly.

This technological improvement represents a step forward in the usability of these complex machines: the language itself rises from a set of levers and LEDs to user panels equipped with simplified displays and clean lines.

DAVE Embedded Systems' KEY ROLE:

DAVE Embedded Systems, with its renowned professionalism and experience, developed a hardware electronic card designed specifically for the customer and for his precise need for work in conditions of absolute safety. In particular, a new ARM9 processor with improved calculation capacity (it was 2007), respecting all automotive standards with extreme care: this solution provides innovative technologies, allowing the crane to switch from a computer-based control system to monitoring funded on smaller, more robust and reliable components that at the same time determine lower consumption. The goal of this project is to focus on the authenticity of the customized solution, smartly solving these specific needs that allow no margin of error. Last but not least also the Product Life Cycle Management was really important so a new solution based on ARM Cortex-A8 was released on 2011 granting a full product availability since 2021 so 15 years from the creation.

ABOUT THE CUSTOMER:

The Company develops heavy-duty vehicles worldwide, also providing the associated services throughout the product's life cycle. It interfaces with businesses belonging to very different sectors, including shipping, infrastructures and other utilities of fundamental importance nowadays. Their primary need in this project was to implement high-level solutions to replace simpler systems and at the same time guarantee efficiency, safety, and ease of use. By relying on the extensive capacity of DAVE Embedded System in the design of CPU ARM architectures, they were able to create a product of the highest quality that respects all the strict rules laid down by the sector.

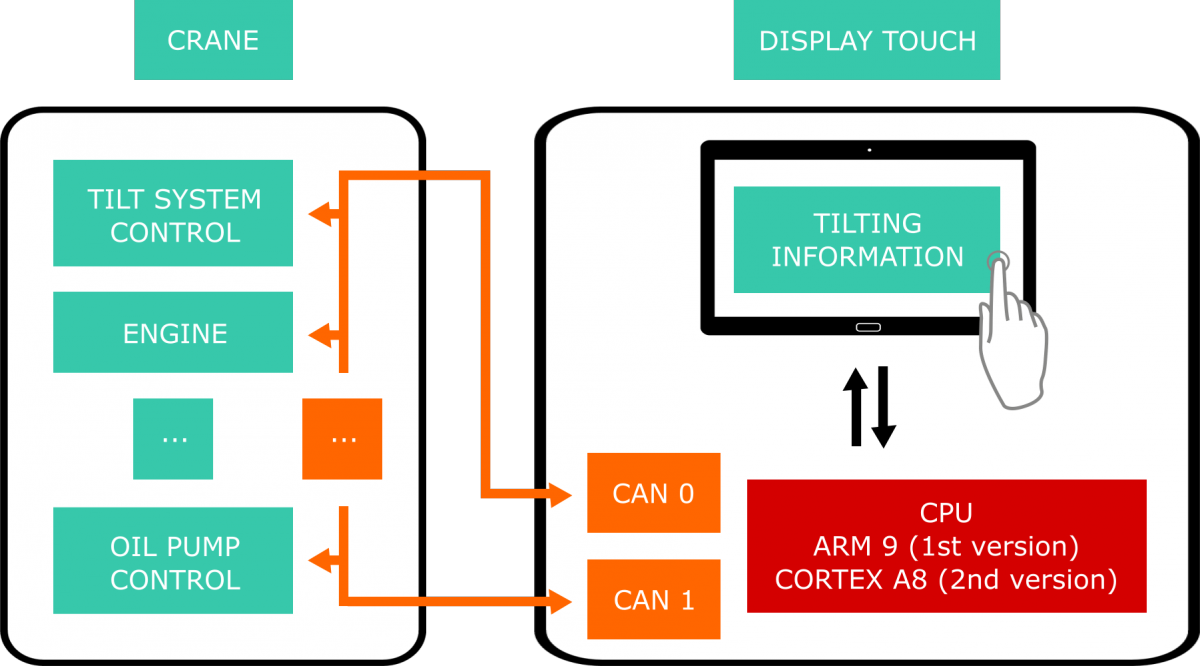

APPLICATION BLOCK DIAGRAM:

The functionalities of this complex project can be better explained with the following application block diagram:

Benvenuti nel portale per la richiesta di informazioni tecniche di DAVE Embedded Systems!

Si prega di compilare i campi sottostanti. Il team di supporto si prenderà cura di te in massimo 24 ore!

Benvenuto nel sistema di documentazione di DAVE Embedded Systems. Si prega di compilare i campi richiesti per ricevere il tuo documento! Grazie!

Utilizziamo cookie per personalizzare i contenuti, per avere statistiche sul traffico e per migliorare la tua esperienza nel nostro sito web.

Per maggiori informazioni sui cookie che utilizziamo ti preghiamo di leggere la nostra Informativa sui cookie e a cliccare su "Modifica preferenze" per personalizzare il modo in cui il sito utilizza i cookie. Cliccando su "Consenti tutti i cookie" dai il consenso all'utilizzo di qualsiasi cookie da noi utlizzato.

Questi cookie sono necessari per il funzionamento del sito Web e non possono essere disattivati nei nostri sistemi.

È possibile impostare il browser in modo che blocchi questi cookie o ne avvisi l'utilizzo, ma alcune parti del sito non funzioneranno. Questi cookie non memorizzano alcuna informazione personale identificativa.

Questi cookie ci consentono di contare le visite e le sorgenti di traffico in modo da poter misurare e migliorare le prestazioni del nostro sito. Ci aiutano a sapere quali sono le pagine più e meno popolari e vedere come i visitatori si muovono nel sito.

Tutte le informazioni raccolte da questi cookie sono aggregate e quindi anonime. Se non autorizzi questi cookie, non sapremo quando avrai visitato il nostro sito e non saremo in grado di monitorarne le prestazioni.

Seleziona tutti Deseleziona tutti